Manufacture of electric motors for Mountain Bikes / Made in France

Here’s how and where the electric DIY kit for bike is made!

A simple and complex electric motor for bicycles:

Our electric Mountain Bikes motor kit for bike may look simple, but on the contrary is very complex to produce.

The crankset is more expensive than the low-end Chinese competition, but like any high-end product, if you want quality, you need to use quality materials and high-performance machines to produce it.

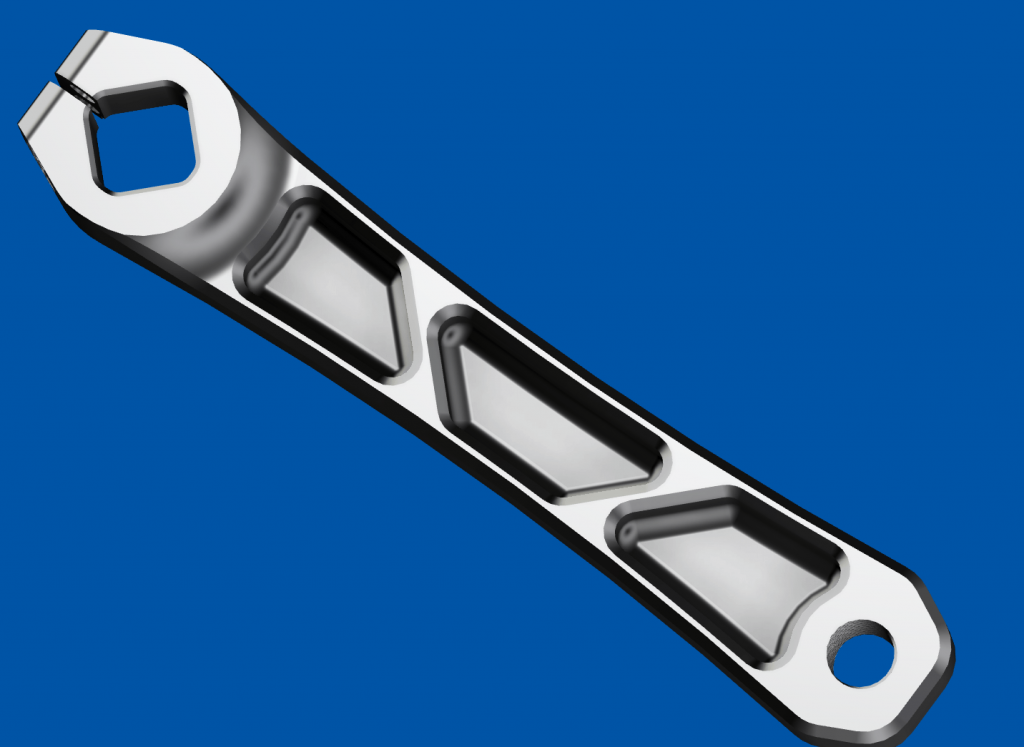

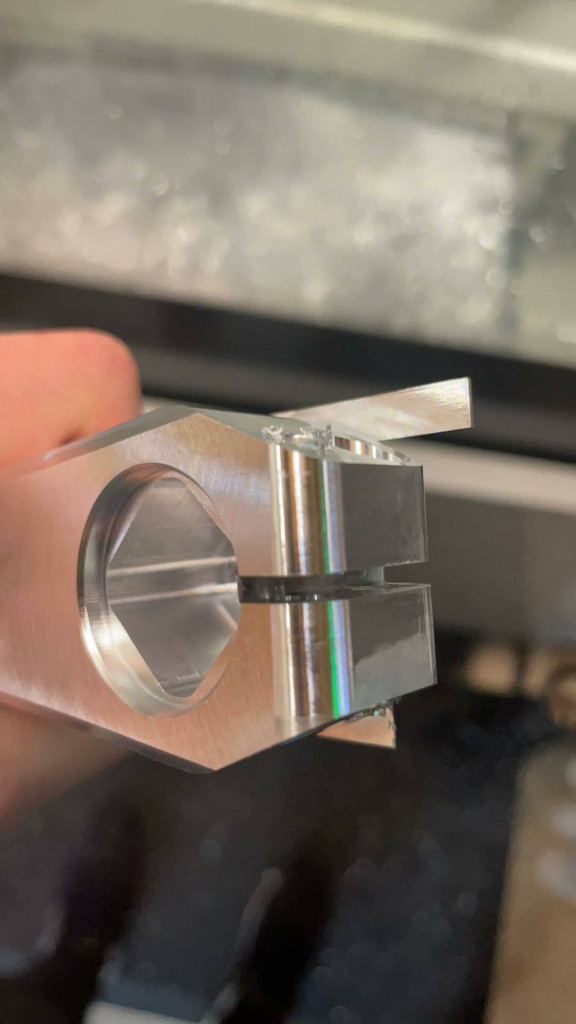

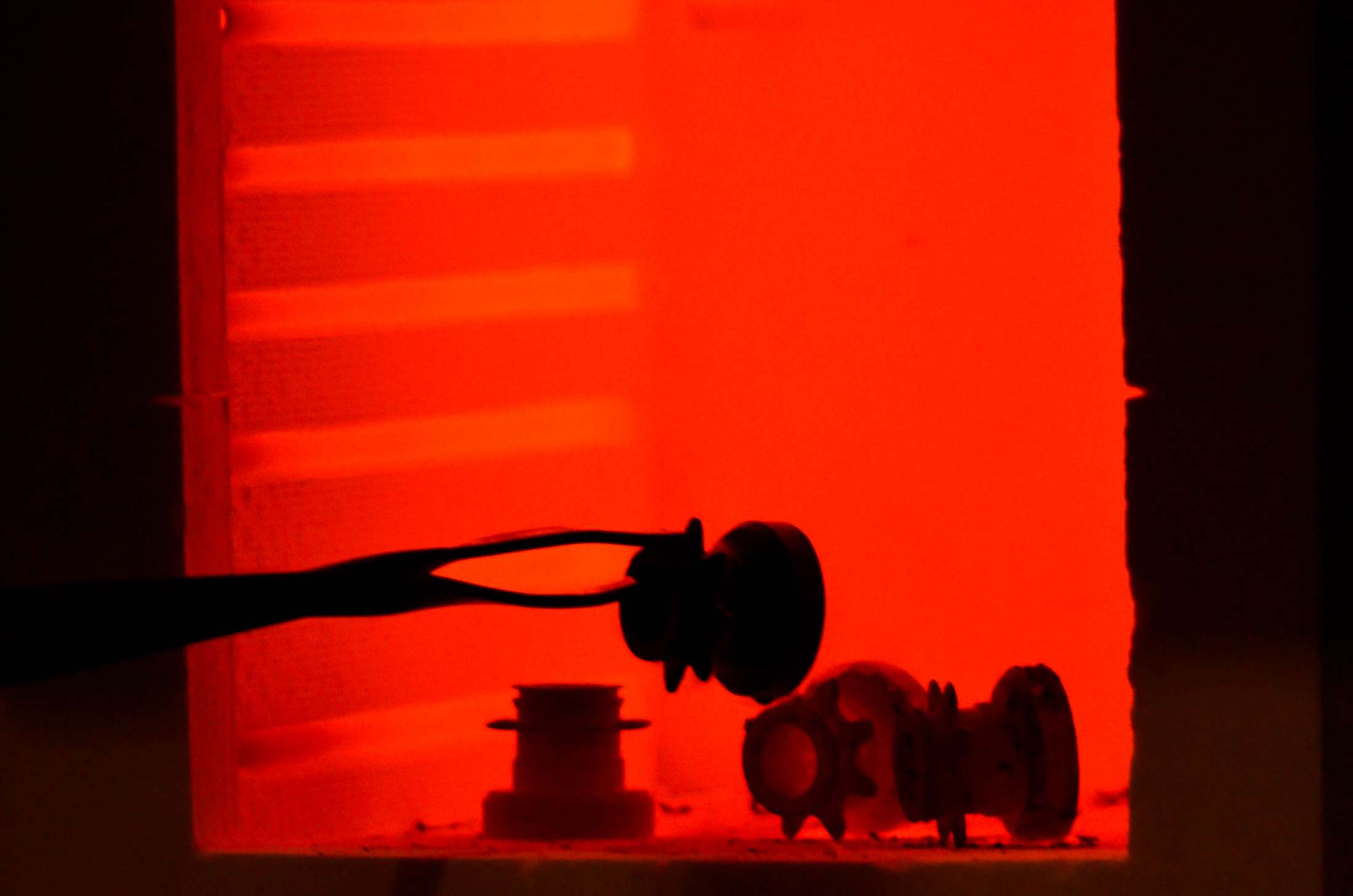

For each adaptable electric kit for Mountain Bikes , we use noble materials such as 7075 T6 aircraft quality aluminum, we machine parts with great precision, which are mostly heat treated after machining.

The engine being only the visible part of the iceberg of the composition of a kit, the parts that compose the kit have a high degree of research and development to define the best.

We use only parts and brands that are quality, narrow wide aluminum 7075 trays, we compose our batteries with Panasonic or LG cells and then assembled at home in France …

Quality.

We strive to have impeccable quality on the parts we manufacture or have manufactured, for example:

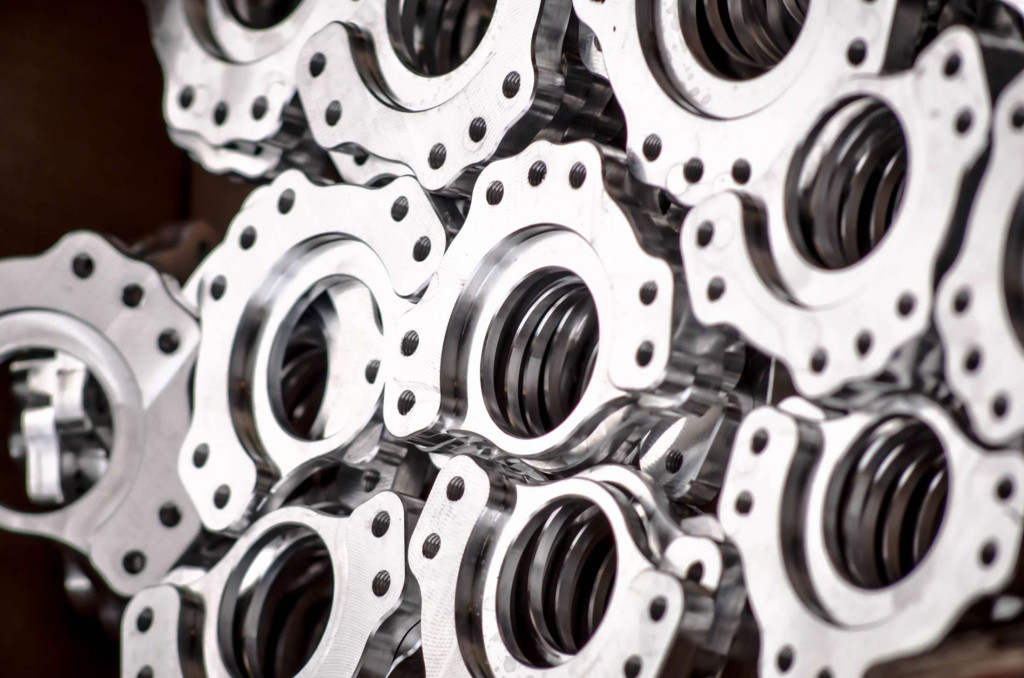

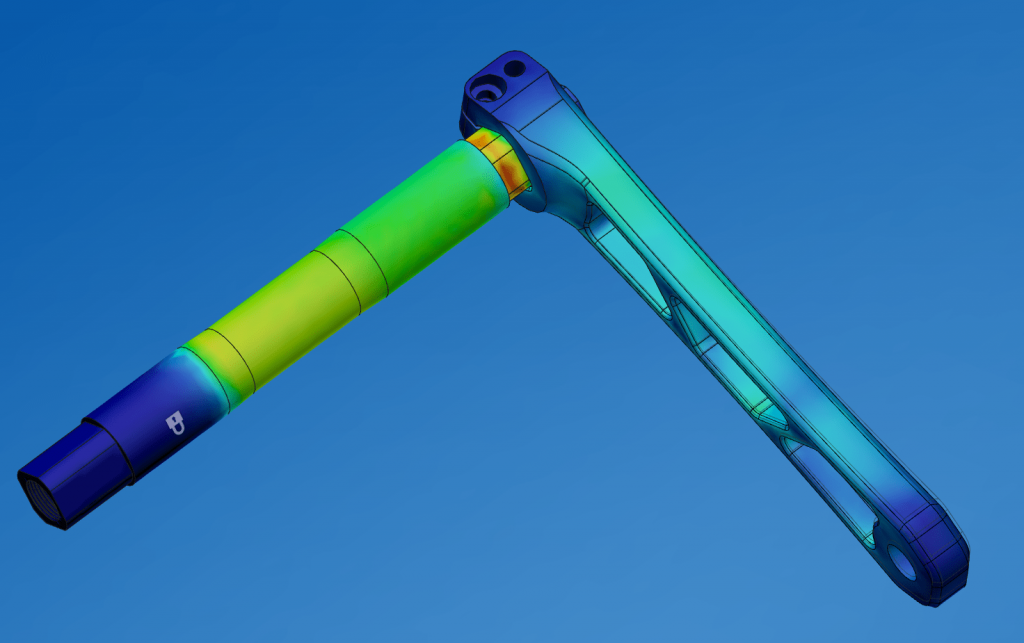

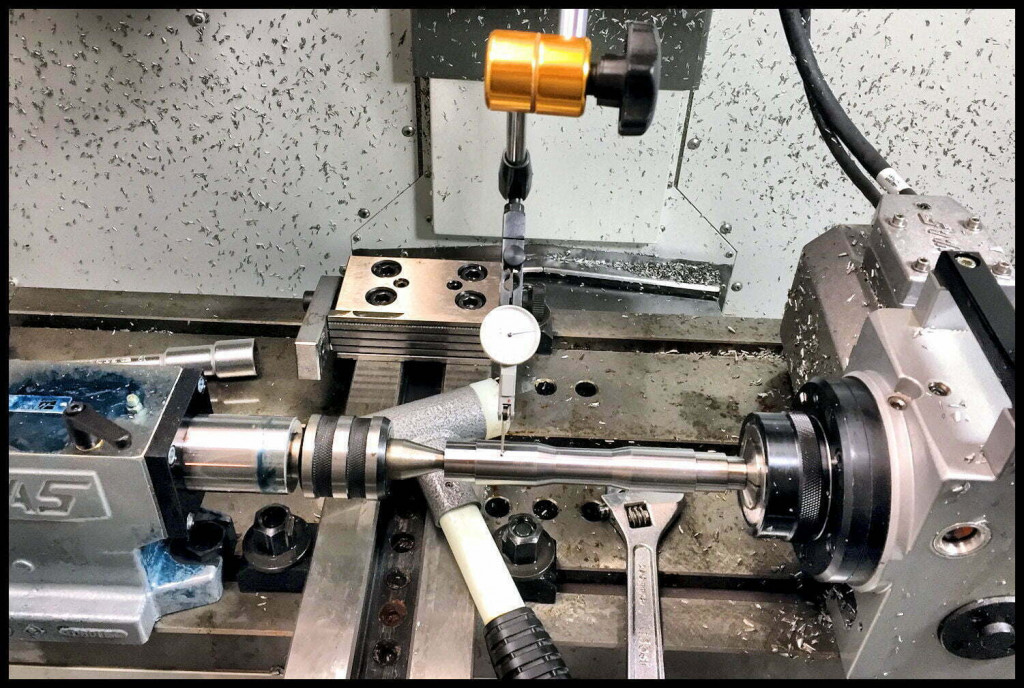

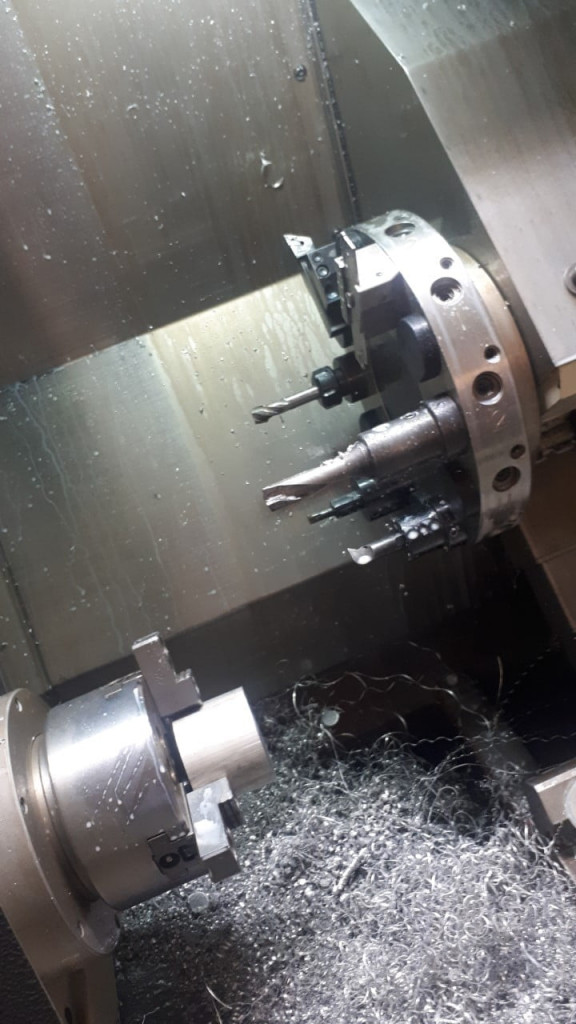

– We use a crank axle made in France in our workshops. The machining of these axes requires very precise dimensions, whether it be for the angles of the splines, their symmetry, the conicity, or the tolerances.

-The adjustment of the diameters requires a very specific tooling with a particular quality control (control on 10 points with a specific numerical tool), the rib is measured before and after heat treatment.

-The same applies to the selection and use of different grades of aluminum or steel for different parts.

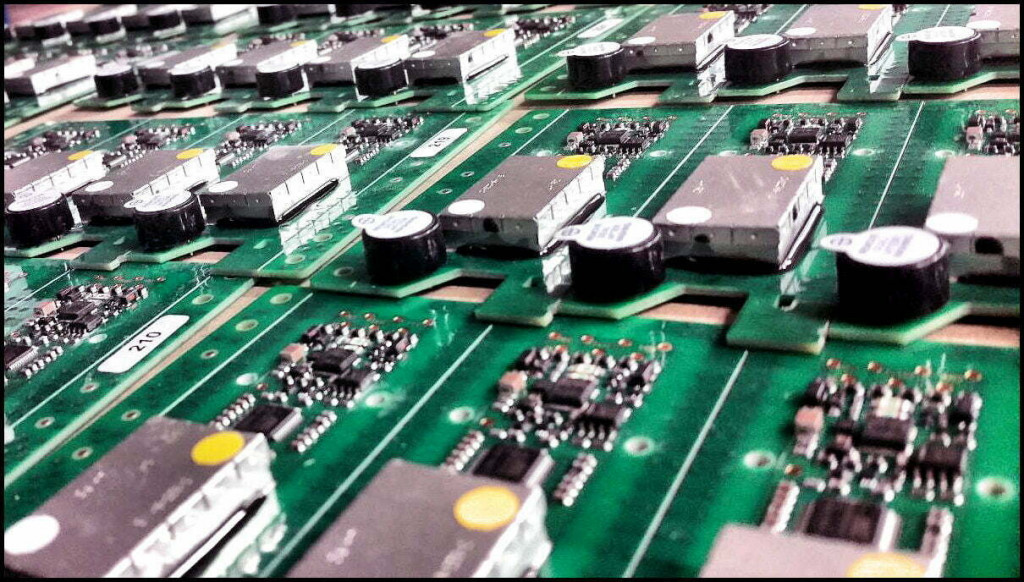

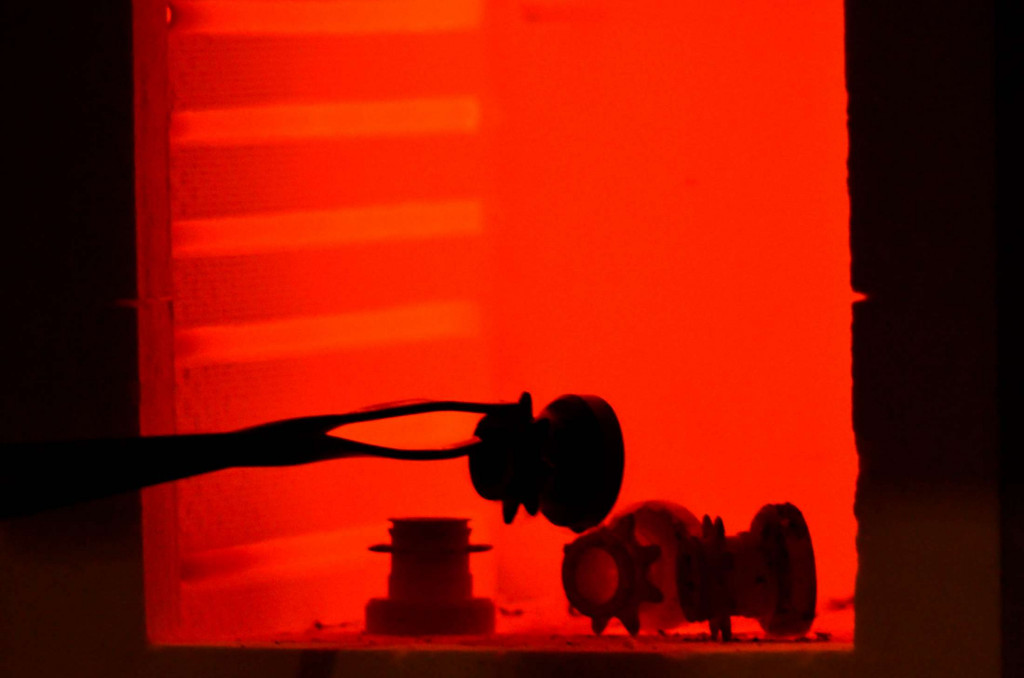

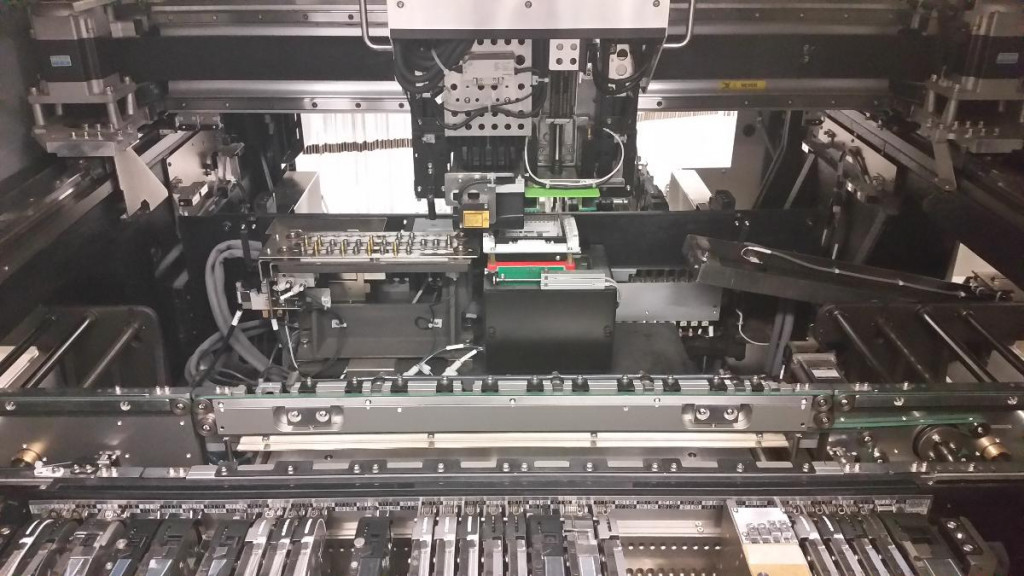

-Manufacture of the plates, heat and surface treatment of the gears and steel axles, anodizing of the various parts according to the type of aluminum, hydraulic press bending of the electronic boxes, manufacture and welding of the electronic system, welding of the batteries with a specific spot welding machine, balancing of the cells.

Despite the apparent simplicity, there are a lot of parts, and a lot of manufacturing and development time for each part, both for the electronic and mechanical parts.

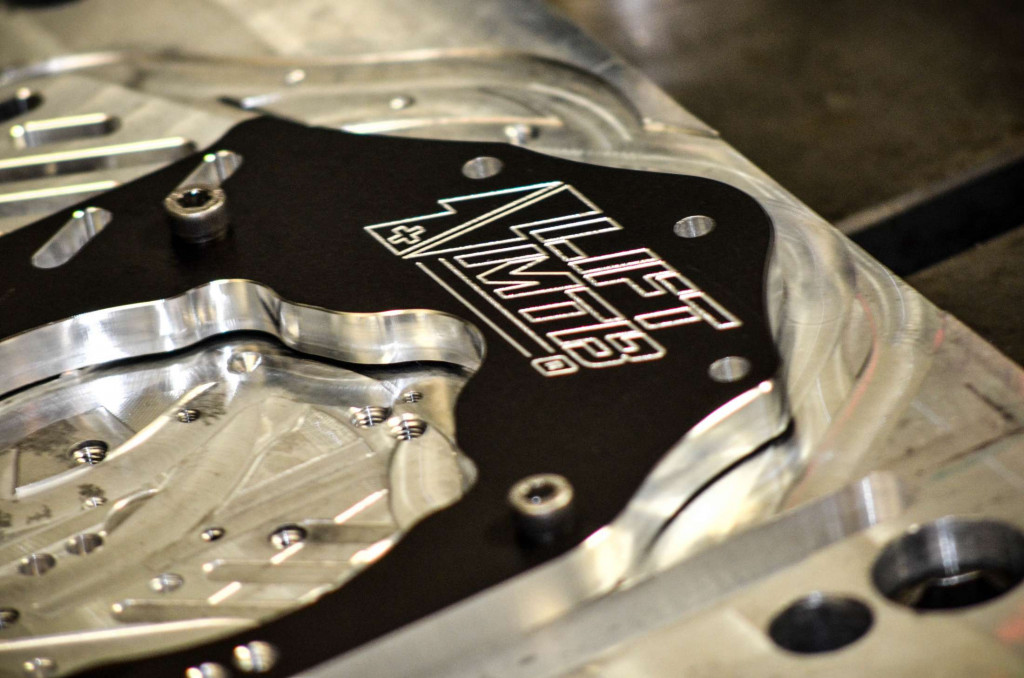

In short, we don’t just put our name on an existing product like some, there is a lot of research and development behind it.

Our kits are made on the line on small series of about 300 pieces per production, we do things ourselves, even if we subcontract by French companies if we do not have the machines sophisticated enough to do so.

We privilege the MADE IN FRANCE for all the stages.

Key figures for the manufacture of the electric bike motor.

Here are some figures:

- Number of company or supplier companies for engine manufacturing: 25.

- Number of references that compose a kit: more than 75.

- Average total manufacturing time for a single kit: 12 hours.

Manufacturing type:

We are mainly engaged in machining, machining of axes and aluminum parts, laser cutting and heat treatment.

But also, burnishing, precision anodizing, plastic machining, laser engraving, preparation of parts, sandblasting, final assembly.

All this while having already defined and knowing the machining tolerances, the steel or aluminum qualities or procedures to be respected.

And of course, using numerous machining centers, some of which cost more than 100,000 euros each.

CNC machine / digital milling machine / sandblasting machine / laser engraving / 3d printer for prototypes / laser cutting machine and water jet cutting / lathe / ect…

Two 3d design and RDM software (material strength test simulator).

To this must be added:

- the purchase of the material.

- the development time of the parts on computer.

- Field testing of the parts with high level pilots, in order to have a real perspective.

These are some of the key points from design to manufacturing that make the added value of our kits.