Technology & use of a brushed motor for electric bike and Mountain Bikes.

The electric motor LIFT MTB uses a brushed motor, technology called BRUSHED, let’s see why we made this technical choice.

Why is brushed technology often criticized?

Brushed is wrongly considered as not performing, because it is associated with technical choices that do not highlight its strengths.

For example, it would be like saying that a Ferrari is a very bad car, having forgotten to mention “in off-road “. “

It is this aspect of the combination of technologies, not optimally compatible, that is mostly misunderstood by the average person. They consider, due to a lack of information, that it is an inefficient or outdated technology.

One can generally read on the forums:

“The

brushless is better!

“This is not true, because it is a truncation of the information.

The characteristics of the brushless motor generally put forward are the following:

1- The brushless motor allows a greater range of revolutions per minute, minimum / maximum, than a brushed motor.

This technology accepts high voltages that allow the maximum rotation speed to be increased without any problem.

However, in the case of the LIFT-MTB electric bicycle motor, the brushed motor is just as effective, as it is not necessary to have a large range of revolutions per minute on a bicycle pedal motor.

Indeed, contrary to a bicycle hub motor which has a fixed gearing, you can play on a pedal motor like the LIFT-MTB on the different speeds at the level of the derailleur of the bike.

It is therefore necessary to remain within the range of engine speeds equivalent to the average velocity of a cyclist.

In simple terms, this means that for optimal performance, the motor must rotate at the same speed as the user’s legs.

It is therefore not necessary to go much higher in the rpm range and to accept strong tensions that would increase the speed of rotation of the crankset, without the cyclist being able to turn his legs fast enough to follow the rhythm of the engine.

2- The brushless motor has little or no resistance, especially when freewheeling, unlike a brushed motor.

Be careful, this resistance can be harmful on an electric bicycle hub motor insofar as it will slow you down each time you stop using the assistance (flat, downhill, slight hill without assistance, etc.).

However, at LIFT-MTB, we have mounted the brushed motor with a mechanical freewheel system at the output of the drive shaft so that the crankset is not braked when pedaling.

With this technical choice, there will be no resistance like on a brushless motor.

3- The brushless motor has no wear on the brushes as in a brushed motor.

Please note that premature wear of the brushes is only valid in the case of an Mountain Bikes (MTB) hub motor that runs very fast and continuously.

Based on this observation, it was not necessary to use a brushless motor on our electric pedal motor system because:

- The LIFT-MTB electric assist does not turn as fast as a hub motor (about 5 times slower).

- All the phases when you are not pedaling (flat, downhill, etc.), the freewheel takes over and the motor is not driven: there is therefore no wear and tear on the brushes as is the case with a wheel that is constantly turning.

It is only when you use the motor that the brushes wear out: which represents a much lower theoretical wear rate.

In practice since 2012 we have never replaced brush with several thousand engines sold for over many season.

4- The brushless motor has a good torque and a good efficiency, especially at high speeds, which allows to have less losses, therefore consuming less.

It is important to keep in mind that all these advantages are very useful for certain applications and only in some very specific cases, such as model making or hub motors in electric bicycle.

Indeed, on a hub motor for bicycles, the wheel turns permanently and sometimes at high speed, which induces completely different constraints than those of a mid drive motor like the LIFT-MTB.

As far as consumption and torque at high speed are concerned, this is an argument that is interesting when using a hub motor, but not so easily verified in the field when talking abouta mid drive motor.

It is true that the brushless has a better performance on paper than a brushed (it would consume less) but this is without counting the losses in the reduction ratio.

Since we have high speed torque in brushless, it requires a higher reduction ratio to not make the crankset turn too fast on a mid drive electric motorr.

Having to reduce the speed will usually require an increase in the number of parts needed for this reduction, creating more frictional losses at the parts, but also additional weight and bulk.

What we gain on the one hand with the use of a brushless motor that consumes less, we lose in part.

If we add to this the fact that brushless technology is more complex and delicate in terms of electrical management, the additional cost of purchasing reliable equipment, we would not be able to offer a quality kit at an attractive price.

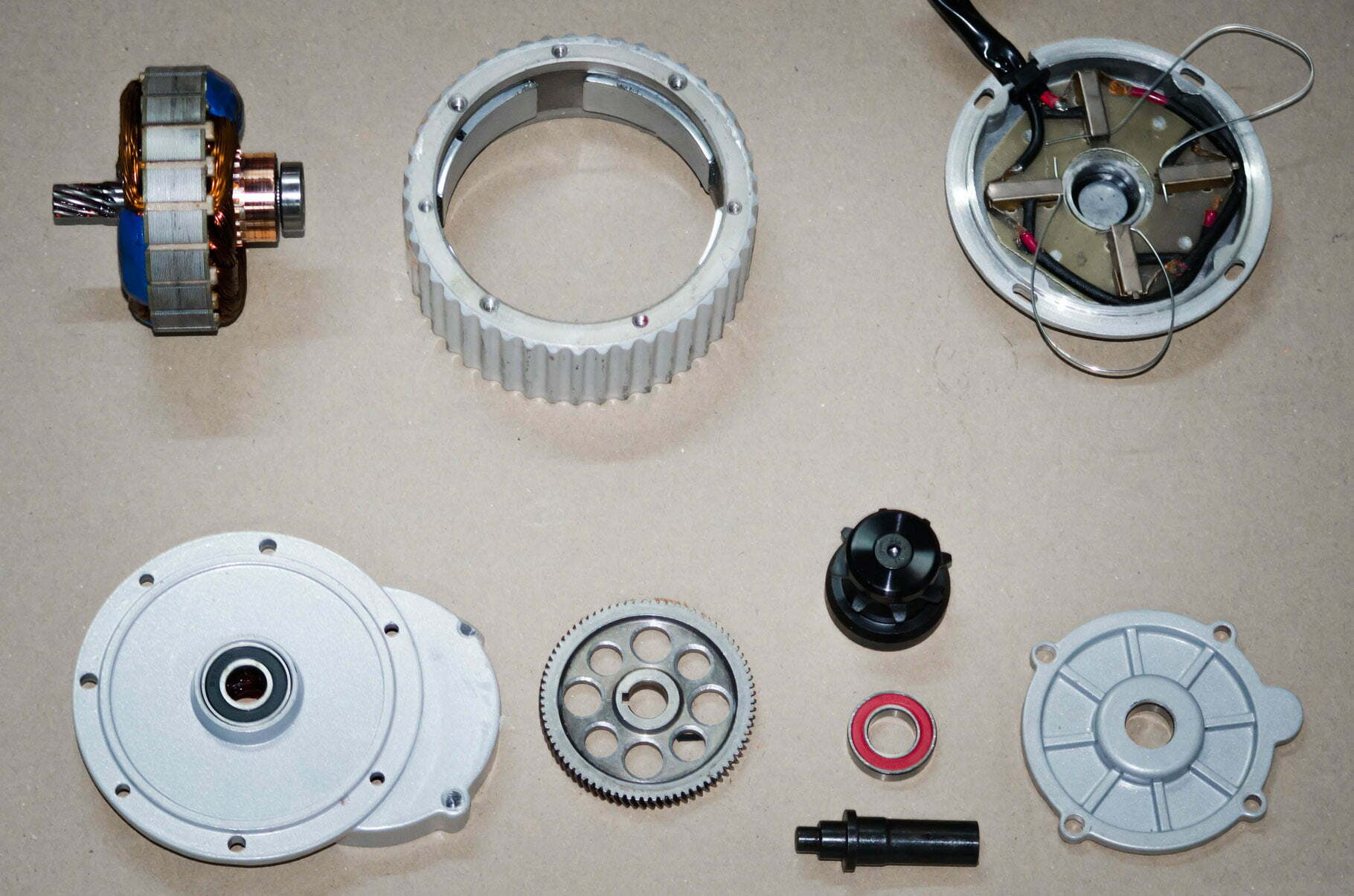

Brushless motor for DIY electric bike

Conclusion:

We could have developed an adaptable electric DIY motor bike kit with brushless technology involving the use of a more expensive motor/controller and a multitude of custom parts in addition such as gears, axles, housings, bearings and specific parts needed to have an efficient gear ratio.

We have therefore chosen to lose 10% of the autonomy, but to offer a kit 50% cheaper, and with a recognized reliability that allows us to open up to a larger majority of customers.

We therefore chose the brushed engine because this technology offered the best ratio

between the different parameters to be taken into account in the design of our product.